Trust EBWA for Electron Beam Welding

We’re committed

Electron Beam Welding Expertise

Electron Beam (EB) Welding is an excellent electron beam welding process for all types of applications and for more than forty years, clients (Aerospace, Military, Energy, and Science) across the globe have trusted EBWA (Roark) to consistently produce precision and quality welds.

Electron Beam Welding Machines

Make: Sciaky

S/N: 9127

Specs: 30KW, 60KV, 500mA

Chamber size: 68″w x 58″d x 78″h

Make: Sciaky

S/N: 8182

Specs: 7.5KW, 60KV, 125mA

Chamber size: 50″w x 30″d x 42″h

Make: Hamilton Standard

S/N: 335

Specs: 6KW, 150KV, 40mA

Chamber size: 52″w x 36″d x 36″h

Make: Hamilton Standard (2)

S/N: 207

Specs: 7.5KW, 150KV, 50mA

Chamber size: 52″w x 36″d x 36″h

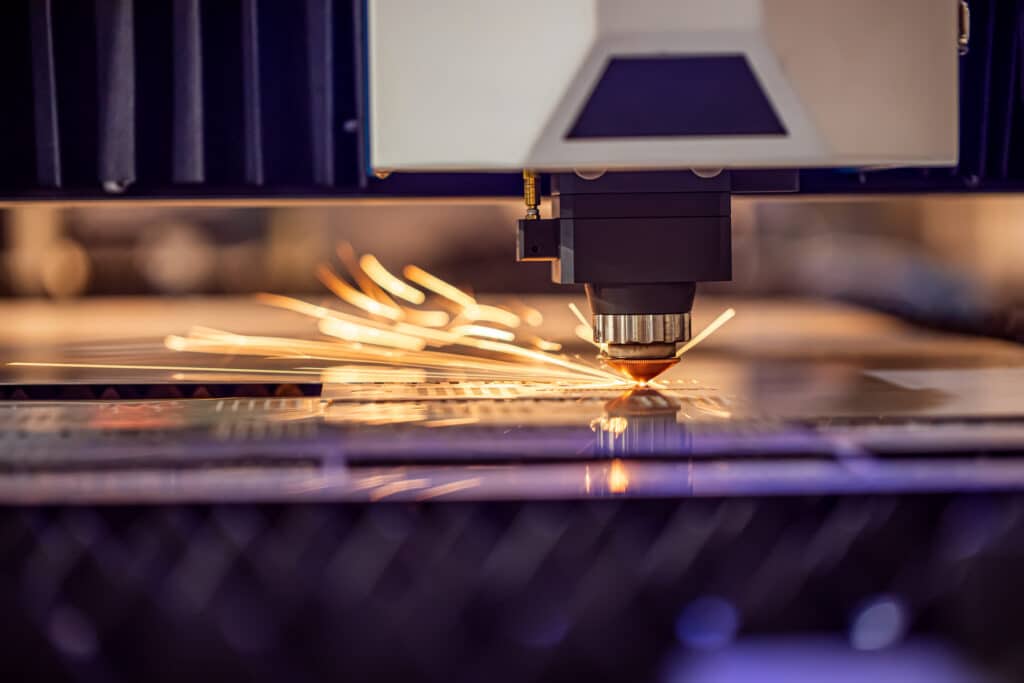

Make: LaserStar Fiber Laser Welder

Model: 8800 Fiberstar Industrial Laser Welder

Specs: 300watt, 3.0KW

Open table, Heavy Duty Rotary

Make: Hamilton Standard

S/N: 365

Specs: 7.5KW, 150KV, 50mA

Chamber size: 52″w x 36″d x 36″h

Benefits of our EB Welding process include:

Deep weld penetration

From 0.05 mm to 200 mm (0.002” to 8”) in single pass

Cost-effective

Cost-effective welding process for large production in automatic mode.

No Sub-Machining

Parts can mostly be used in the as welded condition

All Metals

Welding of all metals even with high thermal conductivity

Additional Services

- Laser Welding

- Arc welding

- Inspection and testing

- Non-destructive testing

- Helium leak detection

- Quick cutting and polishing

Electron Beam Welding for aerospace, energy and science delivered with precision.

Not familiar with Electron Beam Welding (EB Welding)? Let us help.

EB Welding is a line of sight weld method in which a focused stream of high energy electrons are directed at a metal joint to form a uniform weld. EB Welding is an extremely localized and stable welding process and the resulting EB weld is a very narrow weld. Also, due to being a cold and stable process, there is a minimal heat affected zone. Unlike other fusion welding processes it requires no shielding gasses or filler material. The weld quality of an electron beam weld is exceptional and the process is extremely efficient, carefully controlled and fully automated.

Still have questions? Please contact us to learn more about utilizing the Electron Beam Welding process for meeting manufacturing needs.